Whatever your existing skill level, this guide provides valuable insights into shed roof felting and EPDM. Here we explore shed roofing options including the benefits, drawbacks, and installation processes for EPDM and felt materials. Our roofing and shed advice ensures you make an informed decision to protect your shed against the elements while enhancing its durability and aesthetics.

Understanding shed roof felting

Shed roof felting is one of the most common shed roofing materials and is essential for shielding your shed from the elements. Read on as we investigate why felt is a common roofing material by learning about its definition, advantages, disadvantages, and suitability for various roof types.

Shed roofing felt definition

Shed roof felting is the act of covering the surface of the roof with a material that is waterproof and weatherproof, usually, roofing felt. Its main objective is to give another layer of defence against rain, wind, and other natural elements. By serving as a barrier, this layer keeps moisture from penetrating the roof and potentially harming the underlying structure.

Benefits of felt for shed roofing

When it comes to shed roofing, felt offers a wide range of aesthetic possibilities. Its availability in various colours and textures allows for easy customisation, ensuring that your shed's appearance aligns perfectly with your personal preferences. For those mindful of their budget, felt roofing materials present a cost-effective solution. When compared to alternative shed roofing options, felt stands out as an economical choice without compromising quality.

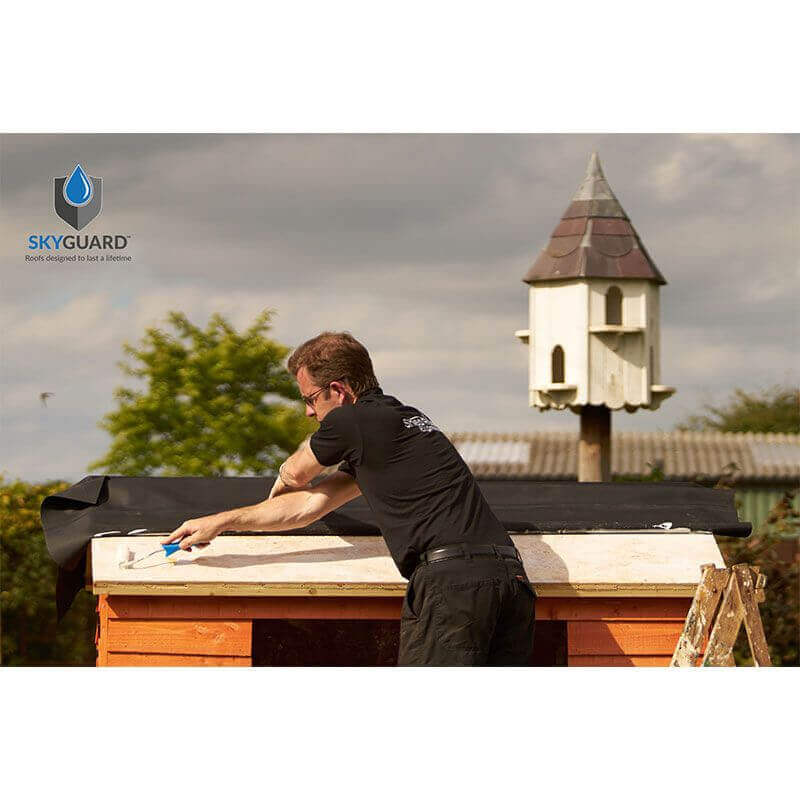

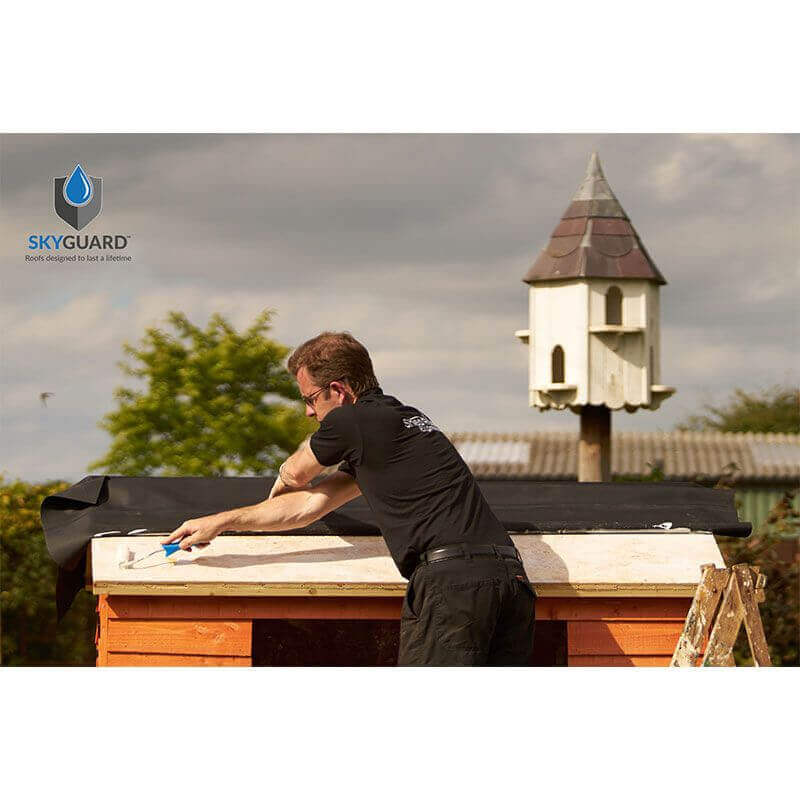

When choosing felt as a roofing material it will quickly become apparent how easy it is to work with. A renowned user-friendly material felt is easy to install and simplifies the roofing installation process. A major reason for choosing felt in recent decades has been its top-quality insulation properties. For maintenance, felt proves to be repair-friendly. In the event of damage, repairing or replacing the shed roof felt can be done without extensive effort or resources.

Felt is versatile and can be used in conjunction with many roofing styles and perfectly cut to the exact size needed. Felt has high water resistance and is the main barrier between the shed underneath and the rainwater, which forever seeks to penetrate inside. Choose felt as a good value option to keep your shed dry and well-protected.

Drawbacks of felt for shed roofing

There are numerous drawbacks to consider for felt roofing for sheds:

- Coping with complexity - complex designs (such as steep roofs, stepped, or elaborate designs) will be more difficult to install due to the practical limitations of felt roofing

- Durability – whilst generally felt is durable, comparatively it is less durable than other more robust roofing materials

- Limited lifespan – although lasting 20+ years, felt roofs have a more limited lifespan than other materials (e.g., EPDM and metal)

- Maintenance - regular maintenance, including resealing, might be necessary to ensure that the roofing remains water-resistant and in optimal condition

- Moisture absorption - felt's susceptibility to moisture absorption underscores the importance of proper sealing during installation; otherwise, it can lead to potential issues over time

- Prone to tears - during installation or harsh weather conditions, felt can be vulnerable to tears or punctures, potentially compromising its integrity

- Susceptibility to Ultraviolet (UV) damage - exposure to intense sunlight and UV rays can lead to felt's gradual deterioration over time, affecting its protective capabilities

Ideal shed roof types for felt roofing

Shed roofs come in various styles, each with its own unique characteristics. Due to its convenience and adaptability, felt roofing is particularly well-suited for specific types of shed roofs. Shed roofs with simple, sloping shapes are generally the best candidates for felt roofing. These straightforward roof constructions allow rainfall to drain freely, reducing the possibility of ponding or leaks.

Furthermore, smaller sheds or structures with less complex roofing needs are ideal candidates for felt roofing due to their low cost and simple installation technique. These variables should influence your selection when contemplating felt roofing for your shed to provide the greatest outcome for your individual roof type and demands.

Roofing a shed: EPDM VS Felt

Listed below is a comparison table for "Roofing a Shed: EPDM vs Felt". The suitability of each material will depend on your specific shed's requirements, budget, and intended use.

|

# |

Feature |

EPDM |

Felt |

|

1 |

Material |

Synthetic rubber membrane |

Bituminous material |

|

2 |

Durability |

Exceptionally durable and long-lasting |

Moderate durability |

|

3 |

Lifespan |

Can last 40+ years |

Requires replacement sooner |

|

4 |

Installation Complexity |

Requires professional installation |

Can be DIY-installed |

|

5 |

UV Resistance |

Excellent resistance to UV rays |

Vulnerable to UV damage |

|

6 |

Maintenance |

Low maintenance requirements |

Regular maintenance needed |

|

7 |

Waterproofing |

Excellent waterproofing |

Good waterproofing qualities |

|

8 |

Flexibility |

Remains flexible in varying temperatures |

Flexible but can harden over time |

|

9 |

Insulation |

Provides some insulation |

Offers minimal insulation |

|

10 |

Installation Cost |

Higher initial cost |

Lower initial cost |

|

11 |

Environmental Impact |

Generally, environmentally friendly |

May have some environmental impact |

|

12 |

Repair Ease |

Repairs can be challenging |

Repairs are relatively easy |

|

13 |

Suitable Roof Designs |

Accommodates various roof designs |

Best for simple sloping roofs |

|

14 |

Weather Resistance |

Withstands harsh weather conditions |

Resilient but prone to tears |

|

15 |

Long-Term Investment |

Higher upfront investment, better long-term value |

Economical choice for immediate use |

Buy EPDM roof kits from Buy Sheds Direct

Buy Sheds Direct prioritises providing EPDM roof kits over standard shed felt due to its enhanced durability. Shed felt is offered as a roofing choice for certain sheds, though it cannot be purchased as a standalone product. You can find more information about this option by clicking on individual shed listings. Our range of EDPM roof kits spans sizes from 4'x3' to 11'x20', ensuring that we have a suitable kit ready for your specific shed dimensions.

Shed roof felt replacement guide

Below we list twelve steps, which are essential to smooth and accurate shed roof felt replacement or renovation:

1) Assessment

Begin by thoroughly inspecting your shed roof. Look for any signs of cracks, leaks, damaged areas or general “wear and tear.” Leaks especially need attention and need fixing. This preliminary analysis will save time overall and yield benefits. Be sure to identify (and maybe address) any general structure-related concerns as part of the assessment.

2) Gathering materials, tools, and supplies

Gather all the necessary materials before you begin. Nothing is more annoying than having to stop later to get supplies, which can include various kinds of materials, tools, and other roofing supplies.

3) Keep safety in mind

Safety is of the utmost concern while renovating a shed roof, one of the reasons for this is because it entails heights. Make sure you have the appropriate safety equipment, such as gloves, non-slip shoes, and safety glasses, before starting any roofing job.

You should always let someone know when you are working on the shed. Before ascending the ladder, make sure it is completely stable. The area outside where you will be working on the shed needs to have caution tape and barricades added.

4) Removal of old roofing

Whilst taking care of the existing shed structure, it is important to carefully remove all existing roofing materials (e.g., felt, shingles, etc.,) Always dispose of shed roofing materials responsibly and ensure you have a specified clear area for the new roofing installation work.

5) Inspect the underlying shed structure

After removing the former roofing, inspect the underlying shed construction. Address any issues such as decay, damage, or weakened components before advancing. A sturdy foundation guarantees that your new roof will last for many years.

6) Installation of underlay

Install an underlay, such as roofing felt or synthetic membrane, to provide further moisture protection. Underlay increases water resistance and the lifespan of your new roof.

7) Install the new roofing materials

Install the roofing material provided, whether EPDM, felt, or another option. To guarantee proper alignment, tight fastening, and enough coverage, follow the manufacturer's installation instructions.

8) Sealing and flashing

Seams, joints, and edges should be sealed to produce a watertight barrier. To avoid leaks, use flashing around roof penetrations such as vents and chimneys. Weatherproofing your shed requires proper sealing.

9) Add ventilation

Adequate ventilation avoids moisture buildup and keeps the interior environment comfortable. Install vents or ridge ventilation to improve air circulation and reduce the risk of mould and decay in the shed.

10) Add insulation

Consider adding insulation for temperature management if your shed is used for more than just storage. Insulating the roof area improves energy efficiency while also producing a comfortable and usable space.

11) Inspect completed work

Inspect the completed roof replacement thoroughly. Examine the alignment, fastening, and general visual appeal. Before completing the job, address any small flaws.

12) Ongoing upkeep and maintenance

Once the installation work is complete, there will be a need for ongoing regular inspections and maintenance. Our advice is to clear any debris build-up and address minor repairs as quickly as possible. Pro-activeness in maintenance will extend the lifespan of your new roof.

We expect that through adopting these twelve comprehensive steps you will be able to complete your shed roof replacement project.

Other best shed roofing materials and options available

Beyond EPDM and felt, there is a wide selection of shed roofing materials to consider. Each option brings its own unique benefits and aesthetic appeal, allowing you to tailor your choice to your shed's design and your preferences. What makes the best shed roofing material, depends on your own circumstances, budgetary constraints, and décor preferences. Choose from the following for roofing a shed:

- Asphalt shingles

- Clay tiles

- Composite roofing

- Green roofing

- Metal roofing

- Polycarbonate roofing

- Roll roofing

- Slate tiles

- Wood shakes

Final considerations for shed roofing options

Maintaining a well-functioning shed roof is essential to preserving the integrity of your shed and its contents. The comparison between EPDM and felt roofing options should help guide your decision-making process.

Now, armed with insights into the pros and cons of various shed roofing materials, you are ready to take the next step and decide which is the best shed roofing material for your project. Whether you are an experienced DIYer or seeking expert help, making an informed choice ensures a roof that stands the test of time.

Contact and support about replacing shed roof felt

For any enquiries about shed roof replacement, roofing materials, and shed roofing options, do not hesitate to contact Buy Sheds Direct. Whether you are considering the best shed roofing material, need guidance on EPDM vs felt, or are interested in replacing shed roof felt, we are here to help!

Call us by phone on 0333 003 0514. Also, feel free to contact us via email, by completing the contact form on our dedicated contact page. Additionally, live text chat with us by clicking on the app icon for our Live Chat feature.