![How to Soundproof Your Drumming Shed [UPDATED]](https://www.buyshedsdirect.co.uk/media/magefan_blog/drumming.jpg)

A love of drumming may not be shared by the whole family or, indeed, the whole neighbourhood. Therefore, a soundproofed drumming shed, log cabin, or summerhouse is a great 'music room' for all that drumming practice. Of course, it will work just as well with other musical instruments.

If your budget allows, you can employ a specialist company to soundproof your garden building. However, if you are working to a budget and want to try a bit of DIY, our ideas for how to soundproof a shed should help you. You will never fully soundproof your shed; however, you can greatly reduce the sound escaping the shed, even if you are on a budget.

Editor’s Note [12.12.23]:

Our article about how to soundproof a shed was originally published in December 2017. Today, we have massively expanded the article providing upgrades throughout. We have also added the following sections – understanding soundproofing basics, what is the need for soundproofing a drum shed? as well as professional soundproofing a shed solution, materials & tools lists, maintaining soundproofing effectiveness, tips for drummers, legal considerations, and some final thoughts.

Soundproofing a shed basics

Soundproofing a garden shed for drumming is more than just adding foam panels. It is about understanding how sound works and using that knowledge to create a peaceful space. When we talk about soundproofing, we are dealing with two main concepts: sound absorption and sound blocking. They are like two sides of the same coin but work in different ways.

Sound absorption

The main goal of sound absorption is to absorb sound waves inside a shed (or other garden rooms). It is like wiping up spills with a sponge. Acoustic foam (also called closed cell foam) or thick carpets work well for this. Because they capture sound waves and stop them from rebounding around, they prevent echoes. This is particularly crucial in tiny spaces like garden sheds where sound can bounce off the walls very quickly.

Sound blocking

Sound blocking is the process of preventing sound from entering or leaving a space. Think of it as erecting a stronghold around your drum set. Here you can find dense materials like mass loaded vinyl. They are thick and prevent waves of sound from passing through them easily. You do not want your rhythms to seep out and become the newest soundtrack in the neighbourhood while you are pounding away in your shed.

Combine both for the best effect

Combining these two approaches is key for an effective soundproof garden shed. You want to absorb the sound inside to improve acoustics and block it from bothering anyone outside. It is like having your own little sound oasis and essentially you are building a “room within a room”. The right balance ensures you can drum to your heart’s content without any stress about noise complaints or poor sound quality.

Remember, the structure of your shed plays a big role too. If your shed has gaps or thin walls, all the soundproofing materials in the world will not help much. Sealing up any cracks and adding layers to the existing walls can massively improve your soundproofing efforts. Consider it like priming a canvas before you begin painting. When it comes to keeping your drumming sessions quiet and producing excellent sounds, a well-organized shed is essential.

What is the need for soundproofing a drum shed?

It is imperative to properly soundproof an existing structure to become a drumming shed if you wish to practice uninterrupted. It finds a middle ground between your love of drumming and the requirement for peace in the community. Although, we talk about drum sheds in this article, the same principles apply to setting up a music studio:

-

Better acoustics - insulating the shed with soundproofing materials will provide better acoustics

-

Compliance with laws - your efforts will also ensure that you comply with local noise laws and regulations

-

Concentration boost – free yourself from outside airborne noise and concentrate on drumming

-

Enhanced privacy - your drumming sessions will be more private

-

Flexible practice times – practice 24/7, as you will not be restricted to drumming at sociable times, use your drum studio at 3AM if you want to, in your own practice room!

-

Improving skill discreetly - hone drumming techniques discreetly, practice repetitive sequences without causing irritation

-

Neighbourly peace - prevent noise leakage and spills to keep harmonious and peaceful relations with neighbours

-

Noise level control - high decibel levels can be managed to protect hearing

-

Expert recordings – complete your own high calibre recordings and be guaranteed to record free of outside noises

-

Stress reduction – reduce anxiety and stress levels associated with worries about noise pollution

How to soundproof a shed with professional soundproofing solutions

Opting for professional soundproofing services often leads to higher quality results and longevity compared to DIY. Professionals bring expertise and precise techniques that DIY efforts might not match.

Comparison table: DIY vs professional soundproofing

Look at the table below, which breaks down the key differences between DIY and professional soundproofing:

|

# |

Criteria |

DIY |

Professional |

|

1 |

Cost |

More affordable initially |

Higher upfront costs |

|

2 |

Installation time |

Time-consuming process |

Quick and efficient |

|

3 |

Material quality |

Varies widely |

Consistently high quality |

|

4 |

Equipment used |

Basic tools |

Advanced, specialised tools |

|

5 |

Techniques |

Self-learned methods |

Professional, tested techniques |

|

6 |

Labour |

Self-performed |

Expert labour included |

|

7 |

Effectiveness |

Can be hit or miss |

Highly effective |

|

8 |

Guarantee |

No formal guarantee |

Often guaranteed results |

|

9 |

Accuracy |

Prone to errors |

Precise and accurate |

|

10 |

Expertise |

Amateur level |

Deep expertise |

|

11 |

Customisation |

Limited custom options |

Tailored solutions |

|

12 |

Support |

Self-reliant |

Professional support available |

|

13 |

Experience |

DIY learning curve |

Stress-free experience |

|

14 |

Satisfaction |

Personal achievement |

Professional satisfaction |

|

15 |

Maintenance |

Self-maintained |

Professional maintenance |

|

16 |

Knowledge |

General knowledge |

Acoustic specialisation |

|

17 |

Time investment |

Significant personal time |

Saves personal time |

|

18 |

Consistency |

Variable results |

Consistent quality |

|

19 |

Flexibility |

Adaptable process |

Structured, reliable process |

|

20 |

Regulatory compliance |

Self-managed |

Meets legal standards |

DIY guide - soundproofing shed for drums

The title of this article, "How to Soundproof Your Drumming Shed," assumes you will do it yourself. Therefore, the rest of this article focuses on what you need to do to establish a drum shed (or music studio).

Materials required for soundproofing

To effectively soundproof your drumming shed, you will need these specific materials:

- Acoustic foam panels – a great addition to any shed, especially for music practice or recording, as they effectively absorb the sound and reduce echoes

- Acoustic sealant - a flexible sealant, which fills cracks and gaps

- Door sweep - close the space between the floor and the bottom of the door with a door sweep

- Green glue – this noise proofing compound is perfect for reducing sound transmission through walls. It is applied between layers of rigid construction materials

- Mass loaded vinyl (MLV) – a dense material, that blocks out sound, most often this can be used on shedding walls

- Resilient channel – create a decoupling effect to reduce sound transmission through walls

- Soundproof insulation - use acoustic insulation materials such as fibreglass or add acoustic mineral wool insulation. These will fill wall cavities and convert sound energy into heat energy

- Weatherstripping tape – is essential for sealing gaps, particularly around doors and windows

Tools required for soundproofing

Use the tools below for soundproofing a shed for drums:

- Caulking gun – this helps you to apply acoustic sealant

- Drill or screwdriver - necessary for installing resilient channels and potentially in other tasks

- Ladder – naturally, this is for safely reaching areas of height within your shed

- Spirit level - ensures straight and even installation

- Measuring tape - measurements need to be precise when cutting materials, so a measuring tape will prove handy

- Safety gear – ensure you have gloves, goggles, and masks to keep yourself safe during installation work

- Staple gun - ideal for securing materials like MLV and acoustic panels

- Utility knife - handy for cutting foam and MLV to the required size

So, how do you soundproof a shed for drums?

Soundproofing a drumming shed is all about managing the noise and creating the perfect drumming space. It is not just about keeping the neighbours happy, but also about maximising your drumming experience. Here is a rundown on how to soundproof a shed and transform it into an ideal drumming haven without breaking the bank.

Shed frame

When soundproofing your drumming shed, the frame plays a crucial role. It is the backbone that supports all the soundproofing materials you will add. Here is a breakdown of its key components:

- Ceiling joists - these are vital for supporting ceiling soundproofing materials, helping to dampen sound from above

- Door frame - the frame around the door is essential for sealing and insulating the door area, a key spot for sound leakage

- Horizontal beams - they connect the vertical studs, providing stability and a structure for attaching wall soundproofing elements

- Vertical studs - these upright parts of the frame are crucial for mounting soundproofing materials on the walls, forming the primary structure

Flooring

Believe it or not, sound even escapes through the floor. To reduce this, find some old carpet and tack it down like any other carpet. This will reduce sound vibrations from escaping. If you want a more professional look, get yourself some rubber gym mats that interlock together. You will have to cut sections down in order to cover the entire floor; however, this will give you a better finish and further reduce sound output.

Use of floating floors

Floating floors are also a smart move for any drummer looking to soundproof their shed. They work by creating a buffer between your drumming and the ground, thanks to a layer of sound-absorbing material like foam. A floating floor setup not only cuts down on noise escaping your shed but also sharpens the acoustics inside, making your drumming sessions sound even better.

Are concrete floors effective at blocking sound?

Concrete floors in drumming sheds offer excellent sound-blocking properties due to their density. However, they can cause sound to echo inside the shed, so it is a good idea to cover them with rugs or acoustic mats. Adding these softer materials will help absorb sound, improving the internal acoustics while maintaining the soundproofing effectiveness of the concrete floor.

Walls

Depending on your budget, walls are the biggest factor when soundproofing your shed.

First of all, if you can afford it, lots of music stores will sell sound-absorbing foam which are big squares of insulation that have sticky backs and can be stuck directly to a wall. If they are too expensive for you, ordinary insulation foam can be used, and this will still reduce output though not quite as well as the specialised materials.

For you to do this, you will have to essentially build another shed inside your shed. To do this is very easy. Take your rolls of insulation and tack it to the pre-existing wall. Next, use acoustic plasterboard and screw it to the beams of the existing shed wall. This will insulate the shed and reduce the amount of noise escaping. Noise escapes through the screw fittings so assess the wall and use as few screws as possible whilst maintaining a safe build.

Rock Wool is a great insulator and is available in DIY stores. If you want to add even more protection, then ask all your family and friends to save all their egg boxes. Gradually you can cover the walls which will again reduce output and cost next to nothing!

Windows

Windows can be one of the biggest problems when it comes to escaping sound. Especially in older sheds, windows will be a thin layer of glass. All DIY stores have plastic sheets that you can glue to your window, and this essentially doubles up the glass (or you could use double glazed windows) and makes it tougher for sound to escape. For opening windows and natural light make sure the rubber seal is still in good condition and if not replace it as this will lead to an air gap and therefore more escaping sound.

Door

The door on your shed is probably the leading factor for escaping sound when it comes to a shed. Most shed doors will have no rubber seal and air and sound can escape through the tiny gap between the frame and door. A cheap way to fix this is to attach plastic sheeting around the door so that when it shuts it covers the gap. A better solution is to add a rubber seal, trapping and preventing sound from escaping. Key locks should have covers as, again, sound can escape through these.

Roof

We advise that you insulate the roof as you did the walls; however, instead of plasterboard, use plywood as it is a lot lighter but will keep the insulation in place. Again, cover the outer section in egg boxes or acoustic foam as this will reduce sound leakage.

Maintaining soundproofing effectiveness in a drumming shed

Maintaining the effectiveness of your soundproofing is crucial to keep those drumming sessions in your shed on point, without disturbing the peace. Remember, a little maintenance can extend the life and effectiveness of your soundproofing, ensuring your drumming sessions remain your own private concerts. Here is what you need to keep an eye on when soundproofing a shed:

Check for wear and tear

Firstly, always check for any wear and tear in existing materials. Over time, things like acoustic panels or insulation can get damaged or wear out, reducing their effectiveness. Regularly inspect these elements and replace or repair them as needed.

Ensure seals are intact

Eventually all seals will become worn out or damaged. Replacing them periodically is essential to properly soundproof your shed. Any gaps or minor cracks, irrespective of how small will allow sound leakage and destroy the privacy of your drumming and potentially disturb the peace for neighbours.

Cleaning is important!

Cleaning is not just for appeal; or structural integrity of your shed, it is also important for maintaining your soundproofing. Dust, grease, and grime will impact the absorption abilities of soundproofing materials. Take a proactive approach to prevent failures in your soundproofing regime.

Watch out for humidity levels

Excess humidity is an enemy of soundproofing. Dampness will impair the effectiveness of certain soundproofing materials, such as foam-based products. It is also important to remember that a humid shed will also damage your drums and other music equipment, making them susceptible to rust and warping. Consider using a dehumidifier to manage your moisture levels.

Additional tips for drummers

Drum techniques help you strike a balance between drumming effectively and remaining in harmony with others. Here are some additional tips for drummers on volume control, including adjusting drum setup and playing style:

- Acoustic blankets - hang these around the shed for additional sound absorption

- Alternative stick choices - try rods or brushes instead of standard drumsticks for a quieter impact noise

- Bass drum dampening - place dampening material (e.g., such as an old thick blanket) inside the bass drum to soften the thud

- Drum mutes - fit these onto your drums to significantly lower the volume. You can buy drum mutes/silencer pads but many drummers find that tea towels are an equally effective cheaper alternative

- Drum shield - use a drum shield around the kit to contain and deflect sound

- Electronic drum kit - opt for an electronic kit which can be used with headphones for quiet practice. The sound of the impact of sticks on the pads of an electronic drum kit are also very quiet. These kits could be powered by our solar power stations

7. Play lightly - adopt a lighter playing technique to naturally reduce the sound output

8. Practice pads - implement these on drums to lessen the sound during practice sessions

9. Scheduled practice times - plan your practice during hours less likely to disturb neighbours

10. Use low volume cymbals - swap out regular cymbals for low volume ones to reduce sound without compromising on practice quality

Legal considerations and compliance

It is important to consider the legal ramifications and local noise regulations compliance when soundproofing a shed for drums. The following is a list of laws you may want to consider PRIOR to starting soundproofing work:

- Building Regulations Part E – covers building standards, including soundproofing

- Control of Pollution Act 1974 - regulates various types of pollution, including noise

- Environmental Protection Act 1990 - covers statutory nuisance caused by noise-related issues (such as drumming)

- Health and Safety at Work Act 1974 – this relates to drumming if it is used as part of a home business

- Human Rights Act 1998 – noise emissions are mentioned here relating to rights to a private family life

- Local Government Act 2003 - gives local authorities powers regarding noise control, they have more authority than even the police do!

- The Noise Act 1996 - emphasises night-time noise emissions, particularly in residential areas

- The Town and Country Planning Act 1990 – this relates to planning permissions and includes mention of shed modifications

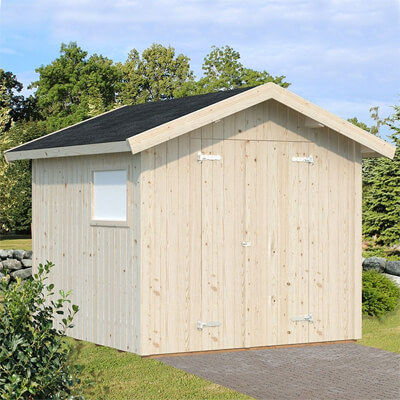

Browse our collection of sheds

So now you know how to turn a shed into a music room for your drum kit and other musical instruments, why not take a look at our extensive range of sheds? Which one will become your music shed?

Concluding thoughts

Wrapping up the guide on soundproofing your drumming shed, passion for music needs its special space. Whether you are a pro drummer or just starting out, soundproofing a shed for drums, and transforming a shed into a soundproof garden room is an exciting journey. Remember, it is not just about silencing the beats for the world outside, but also about crafting an exclusive zone where your creativity can thrive.

With the right approach, your drumming shed can become the perfect retreat for honing skills, without the stress of disturbing the peace. And if you are not up for a DIY adventure, professional soundproofing a shed services are always an option. Either way, it is about striking the right chord between your drumming passion and the tranquility of your surroundings.

Contact Buy Sheds Direct

We are not seasoned experts at how to soundproof a shed, but we think our guide to establishing a drumming shed will be very helpful. Why not view our sheds range now if you need advice about which ones to consider, contact us in these ways:

- Phone - 0333 003 0514

- E-mails - using our contact form

- Text chat - use our live chat app to text chat with us in real-time