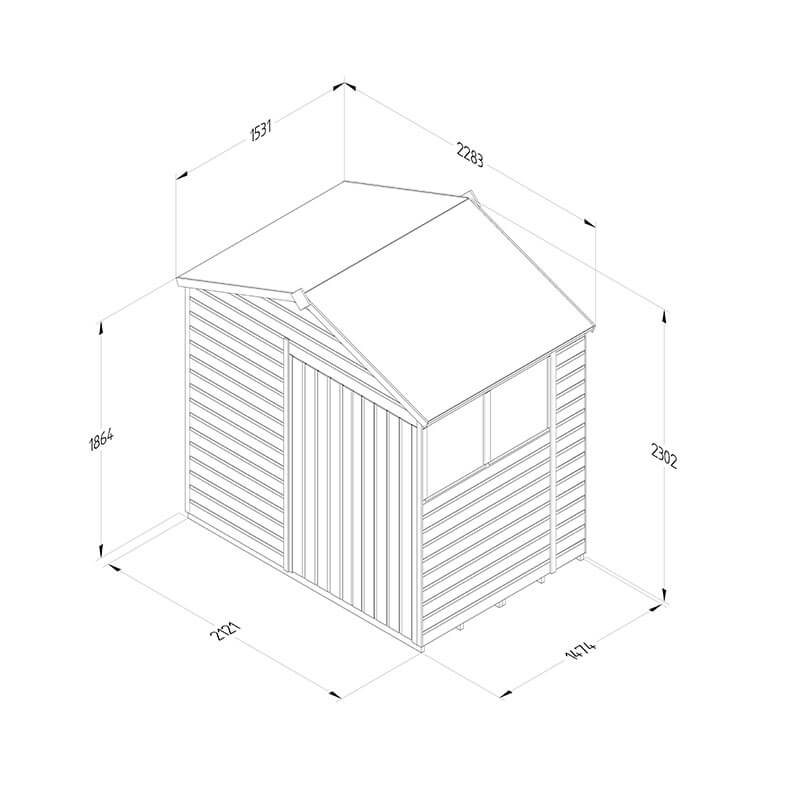

If you want to buy a Great British shed that offers more than just plain, old garden storage, choose a Forest Beckwood 25yr Guarantee Shiplap Pressure Treated Shed. A weather beating home for your tools, bicycles, fishing tackle and more, this particular model is the 7x5 Double Door Apex Shed (2.28m x 1.53m), and here's what makes it special...

Modular Design, Pressure-Treated Wood and the Longest Guarantee on the Market

This garden shed is expertly designed and built by Britain's leading manufacturer of wooden sheds. Pressure treated and supplied with an extraordinary 25-year anti-rot guarantee, which is the longest guarantee on the market, the wood will never need retreating against rot, sparing you the inconvenience of costly, time-consuming maintenance and providing you with an unbeatably durable shed.

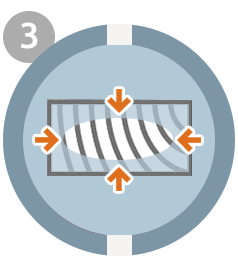

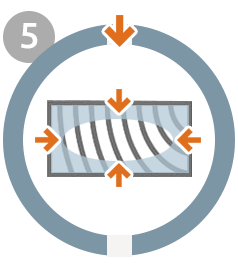

Featuring a complete modular design, this garden shed is delivered to you in smaller sections of interchangeable panels, so you'll find it much easier to assemble than other wooden sheds. This modular design also allows you flexibility with door and window placements, helping you customise the shed to your exact requirements. What's more, with 30% thicker framing, this garden shed isn't just easier to assemble and more versatile than other wooden sheds, it's far stronger too.

A Robust, Weathertight and Supremely Stylish Shed

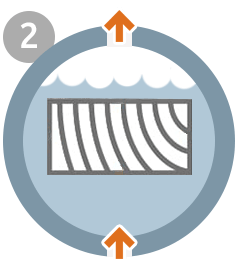

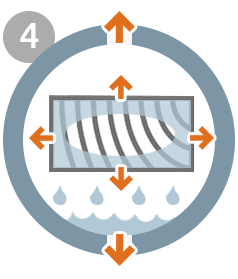

The walls are constructed from 12mm shiplap tongue and groove cladding, on a 28 x 56mm frame, making for a robust and durable garden building. The tightly-interlocking boards ensure the shed remains completely weathertight, while shiplap's scalloped profile provides excellent rainwater runoff.

Expertly made from premium 12mm tongue and groove, the floor is perfectly equipped to accommodate your heavier items and cope with regular footfall. It is supported by pressure-treated bearers, providing a further layer of protection against rot-causing ground moisture.

The roof is built from tough 8mm OSB and fitted with a green mineral-felt cover for complete weatherproof protection. It comes with a traditional apex design, barge boards and eye-catching finials. The wood's smooth-planed finish perfectly rounds off the shed's timelessly attractive appearance.

Security Doors and Shatterproof Glazing

You can access this shed via wide double doors, which can be installed in different positions to suit the orientation of your garden. Ledged and braced for extra strength and to prevent dropping/ movement, these doors are fitted with hidden security hinges and a pad bolt to give you peace of mind that your valuable tools are safe (padlock not included).

Once inside, you'll find the high roofline allows plenty of headroom, along with the chance to store taller items. The 2 3mm acrylic windows provide plenty of natural light - perfect if you're storing important equipment or working on DIY projects. These windows are completely shatterproof and will neither discolour nor fade over time. You can install them in a variety of positions - again, the choice is yours.

Ethically Sourced and Locally Built for a Brighter Future

This 7x5 shed is handcrafted in Great Britain from FSC® certified British wood, so the timber is sourced from sustainable, well-managed forests and the manufacturing process's environmental impact is kept to a minimum.

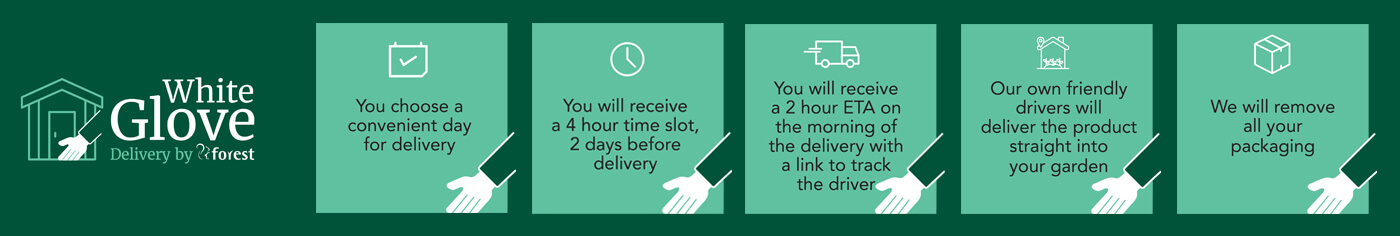

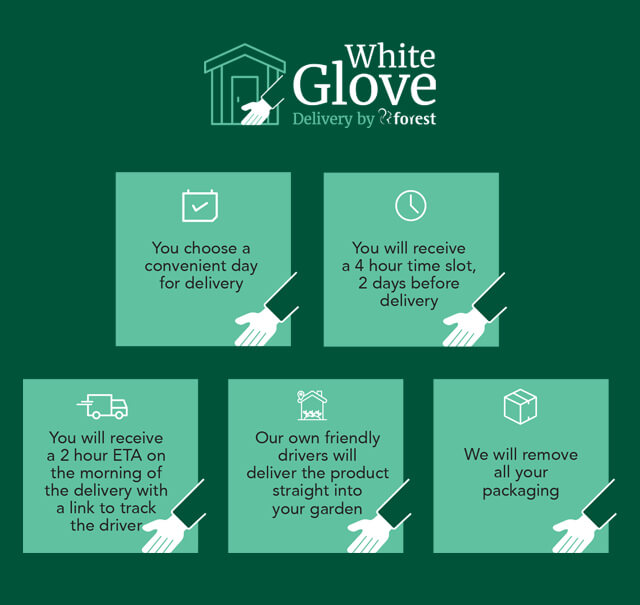

Forest's White Glove Delivery Service

Free delivery is available to most UK postcodes using Forest's White Glove Service. This means the shed is delivered straight into your garden, with all of the product packaging removed. This shiplap shed comes with a full set of fixings and clear instructions to help you achieve a straightforward assembly.

Optional Upgrades

If you'd rather the professionals assemble the shed for you, we offer a competitively-priced installation service as an optional upgrade. You can purchase a pressure-treated shed base as an optional extra too.

- Expertly built in Great Britain from FSC® certified British wood

- Pressure treated with an extraordinary 25-year anti-rot guarantee - the longest guarantee on the market

- Maintenance freedom - wood never needs retreating

- Complete modular design for a much easier assembly, versatile door/ window configuration, and far stronger shed

- 12mm shiplap tongue & groove cladding on a 28mm x 56mm frame

- Premium 12mm tongue and groove floor

- Pressure-treated floor bearers

- Tough 8mm OSB roof with weatherproof felt covering

- Ledged and braced security doors with hidden hinges and pad bolt (padlock not included)

- 2 shatterproof 3mm acrylic windows

- White Glove Delivery Service straight into your garden

- Made by Forest, the shed experts - over 50 years in the business and over 2 million sheds made!

- Choose a Beckwood shed from a huge range of designs and sizes

- Professional installation service and pressure-treated shed base available as optional upgrades

Shed Base Options

Wooden Shed Base Kit

As an alternative to laying slabs or concrete, this shed base is a faster, more cost effective DIY solution.

The wooden shed base consists of a framework that is made from UC4 incised timber which has been pressure treated. The pressure treatment ensures that the framework is robust and is guaranteed to resist rot for an impressive 15 years.

Size of base: 7.5cm (h) x 212.1cm (w) x 147.1cm (d)

Plastic Shed Base Kit

Quick and simple to install, the 7x5 plastic shed base kit is ideal for avoiding the hassle of laying slabs or concrete when preparing a base for a new shed. Its interlocking design makes it easy to put together and, though lightweight, it provides a very strong and durable base for the shed. Made from 100% recycled plastic, this shed base is eco-friendly. Also, it can be reused if the shed is repositioned. The base allows for ventilation and drainage under the shed, helping to keep the shed floor dry.

To install the base, simply interlock the square grids together and lay onto a firm, level area of ground. We recommend using 15kg of 10mm pea gravel per square (gravel not included). Each square is 500 x 500 x 40mm. This pack contains 15 squares and heavy-duty, commercially-graded weed membrane.

Please be advised that we do not assemble plastic shed bases as part of our installation service. You must prepare the base yourself in advance of the installers' visit.